Email us now!

Polypropylene Olefin fabric is a popular and versatile material used in a wide range of applications. Known for its durability, resistance to fading, and easy maintenance, this fabric has become a preferred choice for various indoor and outdoor uses. Understanding the main types of Polypropylene Olefin fabric is essential for selecting the right material for specific projects.

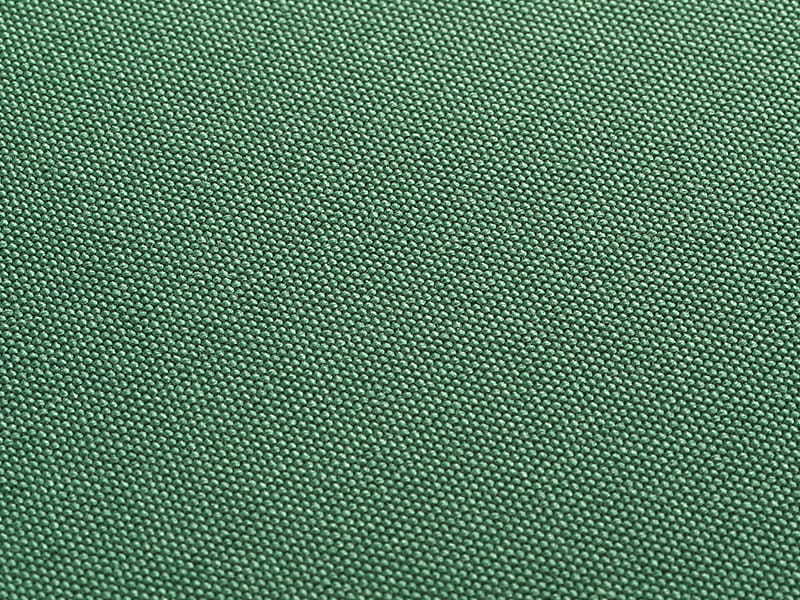

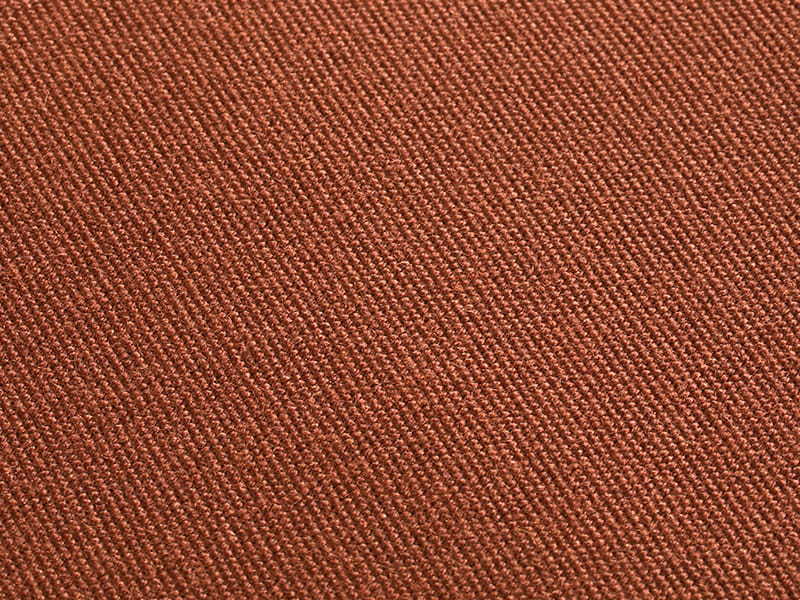

Woven Polypropylene Olefin fabric is a robust and durable option, constructed by interlacing polypropylene fibers in a traditional weaving process. This type of fabric is known for its strength, making it suitable for heavy-duty applications. It is commonly used in outdoor furniture, backpacks, bags, and other products that require a combination of strength and weather resistance. Woven Polypropylene Olefin fabric comes in a variety of colors, making it a versatile choice for both indoor and outdoor upholstery and decor.

Non-Woven Polypropylene Olefin fabric is made by bonding polypropylene fibers together using heat, chemicals, or mechanical processes. This results in a fabric that is lightweight, breathable, and cost-effective. Non-woven Polypropylene Olefin fabric is often used for disposable items such as shopping bags, surgical gowns, and hygiene products. Its versatility and affordability make it a popular choice in various industries, including agriculture, medicine, and packaging.

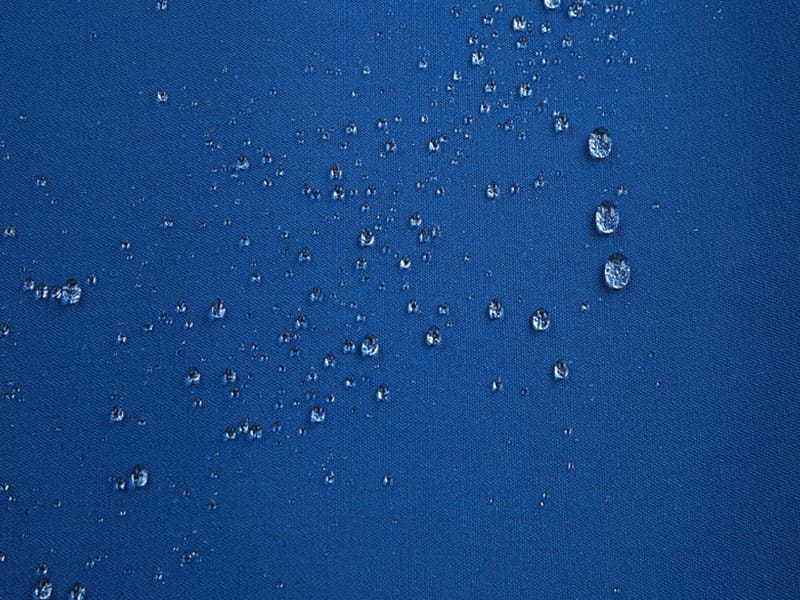

Spunbond Polypropylene Olefin fabric is produced using a specific spinning process that creates continuous filaments of polypropylene. These filaments are then bonded together to form a strong and durable fabric. Spunbond Polypropylene Olefin fabric is resistant to moisture, mold, and mildew, making it an excellent choice for outdoor furniture and upholstery. It is also commonly used in geotextiles, agriculture, and filtration applications due to its high tensile strength and resistance to chemical degradation.

Meltblown Polypropylene Olefin fabric is manufactured using a melt blowing process, where polypropylene pellets are melted and blown into fine fibers. These fibers are then collected and bonded together to form a non-woven fabric. Meltblown Polypropylene Olefin fabric is known for its excellent filtration properties, making it ideal for use in medical masks, air filters, and oil-absorbent pads. It is also used in the production of wipes, diapers, and other hygiene products due to its soft and absorbent nature.

Needle-punched Polypropylene Olefin fabric is created by mechanically entangling polypropylene fibers using barbed needles. This process enhances the fabric's strength and stability, making it ideal for applications that require resistance to tearing and fraying. Needle-punched Polypropylene Olefin fabric is commonly used in landscaping and erosion control products, as well as in automotive interiors and floor coverings. Its ability to withstand heavy foot traffic and exposure to the elements makes it a durable and reliable choice for outdoor applications.

Laminated Polypropylene Olefin fabric is created by bonding a layer of Polypropylene Olefin fabric to another material, such as foam or non-woven backing. This lamination process enhances the fabric's strength, cushioning, and insulation properties. Laminated Polypropylene Olefin fabric is commonly used in upholstery and padding for furniture, automotive seating, and mattress covers. Its ability to provide added comfort and support makes it a sought-after choice in these applications.

Polypropylene Olefin fabric offers a plethora of options for various applications, from heavy-duty outdoor furniture to disposable medical products and filtration materials. Understanding the main types of Polypropylene Olefin fabric allows manufacturers, designers, and consumers to make informed choices based on specific project requirements.

English

English 中文简体

中文简体